Make Your Kitchen Smarter with FryBot™ and PizzaBot™

Labor shortages, high turnover, and the constant push for consistent food quality aren’t new challenges in commercial kitchens. But in a competitive foodservice environment, they’re becoming more pressing—and costly—than ever. Kitchens are busier, margins are tighter, and errors can lead to wasted food, frustrated staff, or unhappy customers.

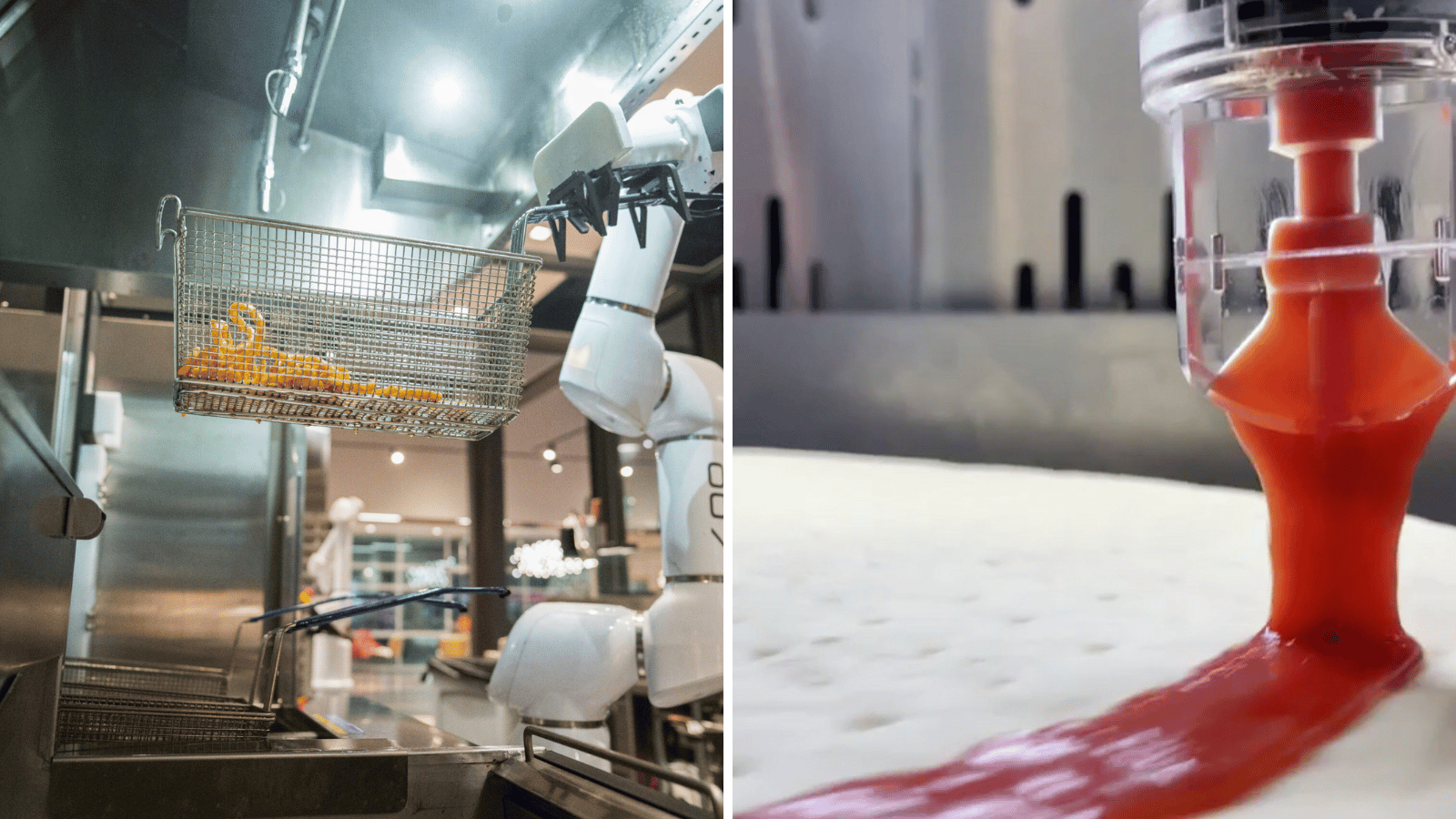

The solution? Automation. Tools like L2F’s FryBot™ and PizzaBot™ are transforming kitchen operations, tackling these pain points head-on while offering a safer, more efficient path forward.

Embracing Automation in Commercial Kitchens

Automation is no longer just a concept for high-tech manufacturing—it’s becoming essential for foodservice operators. With high turnover rates and difficulty finding qualified staff, automation fills critical gaps by performing repetitive tasks faster, safer, and with unmatched precision.

Tools like FryBot™ and PizzaBot™ address labor shortages, improve safety, and deliver consistent food quality. These technologies go beyond solving surface-level problems—reshaping workflows, improving kitchen operations, and helping businesses meet rising customer expectations. In today’s foodservice landscape, embracing automation is a must for staying competitive.

Labor Efficiency with PizzaBot™ – Free Up Your Team to Focus on Customers

Labor-intensive tasks like topping pizzas can be time-consuming and prone to error, especially during peak periods. PizzaBot™ solves these issues using precision automation, ensuring every pizza is perfectly sauced and topped every time. By taking on these repetitive tasks, PizzaBot™ allows team members to focus on customer service and other high-value responsibilities.

This shift reduces the risk of human error, enhances productivity, and helps kitchens maintain efficiency even when staff numbers are limited. PizzaBot™ also minimizes downtime by streamlining production during rush periods, giving operators a much-needed edge.

Consistency and Waste Reduction with FryBot™ – Simplify the Frying Process

Frying food to perfection isn’t just about taste—it’s about meeting customer expectations every time. FryBot™ ensures that fried foods are cooked to exact specifications, delivering uniform results across every batch. You could have the best fryer filtration in the world, but if the fryer isn't used properly, customers might get one batch of amazing fries one day and overcooked fries on another. This consistency keeps customers returning and reduces waste by optimizing ingredient use and extending oil life through precise cooking protocols.

Additionally, FryBot™ reduces the need for manual oversight, allowing staff to concentrate on other tasks while ensuring the fryer operates at peak efficiency. These savings quickly add up for high-volume kitchens, improving profitability without sacrificing quality.

Hot fryers are among the most dangerous pieces of equipment in a commercial kitchen, posing risks of burns and other injuries. A 2023 Kitchen Innovations Award winner, FryBot™ takes on these hazardous tasks, minimizing the likelihood of workplace accidents. By automating repetitive and high-risk frying tasks, FryBot™ not only protects employees but also reduces operator liability concerns.

With fewer injuries, kitchens can avoid costly downtime and worker compensation claims. Plus, when staff are relieved of dangerous, tedious work, their morale improves, leading to better retention and a more positive work environment. In a competitive hiring market, these factors can make a significant difference.

The Future of Foodservice Automation

PizzaBot™ and FryBot™ are more than innovative tools—they’re the future of foodservice. These solutions enable kitchens to navigate labor challenges, improve safety, and deliver consistent quality, all while driving profitability. By integrating these technologies, operators can reduce dependence on unpredictable staffing levels and ensure their kitchens run smoothly, no matter the circumstances.

As automation continues to evolve, operators adopting these tools will position themselves for long-term success. Investing in tools like these doesn’t just future-proof your kitchen—it builds a more thoughtful, safer, and more efficient operation today.

Automation is no longer optional for foodservice businesses striving to stay competitive. With FryBot™ and PizzaBot™, operators can address critical challenges while creating a safer, more efficient kitchen for their teams and customers.

Contact us to get hands-on experience on how automation can help your commercial kitchen flow smoothly: